Satellite

Tracking Station Motion Control

Team

Members:

Anne Burnham, Marcin Lenart, Christopher Velez,

David Weyburn

Advisors: Dr. Ronald Stearman,

Thomas Campbell

May

7, 2003

Aerospace Engineering

and Engineering Mechanics Department

The

University of

Texas at Austin

Go to Table of Contents next>

Errata

-

Section three has been

deleted from the final report; hence, section two leads directly into section

four.

-

All references to the

PXI-7734 should instead be references to the PXI-7344.

Abstract

At

the beginning of the semester, the tracking station, which was acquired from

the U.S. Air Force in 2002, was only capable of manual motion-control from the

roof of W. R. Woolrich (WRW) Laboratories.

Remote control of the dish from the Satellite Design Laboratory (SDL) is

necessary for the station’s future application in the Formation Autonomy

Spacecraft with Thrust, Relnav, Attitude, and

Crosslink (FASTRAC) program. The goals

of this project were to design and implement dish motion sensor arrays and to

create an application for manual and automated dish control. The two sensor arrays contain three

magneto-resistive sensors. One array

monitors horizontal motion of the dish, and the other monitors vertical motion

to prevent over-rotating and damaging the wires. The user interfaces with the application

through a Graphical User Interface (GUI).

Manual Control, Go-To, and Follow functions of the motion-control

application implement user inputs to command the motor to move to a specified

location and to follow a specified path.

The team completed the sensor array design and tested a sensor circuit.

Manual control and Go-To functions were also written, and limited software

control of the dish has been achieved.

LiNC determined that the dish motors do not output an index pulse as

required by the National Instruments (NI) Motion Controller. As a result, the software could not be used

to control the dish for more than 5 seconds at a time. Future design groups may attempt to

manipulate the pulse-encoded output of the motor to locate or emulate an index

pulse or abandon the controllers entirely. Once extended remote control is

obtained, the Follow function is written, and the sensor arrays are installed,

satellite tracking can take place.

Acknowledgements

LiNC would like to thank Dr. Ronald

Stearman for giving us the opportunity to work on this design project. We would also like to thank Tom Campbell and

Dr. Glenn Lightsey for their help in completing the task set before us. Of course, without the overly generous support

of the US Air Force and National Instruments, none of this would be

possible. Thanks also to Honeywell for

their contribution and to the UT Aerospace Department’s Rube Goldberg team for

its tacit agreement to let us use some of their equipment.

<previous Go

to Table of Contents next>

In

2002, Dr. Glenn Lightsey, associate professor in the Department of Aerospace

Engineering at the University of

Texas,

established the Satellite Design Lab (SDL).

Housed on the fourth floor of the W.R. Woolrich Laboratories of the UT

campus, the SDL was established with “the goal of inspiring students in science

and technology through hands-on participation in actual space projects”

[Lightsey]. The SDL was intended to track and communicate with satellites and

to provide an area for the development and construction of satellites and

satellite components. In late 2002

construction began on the UT Satellite Tracking Station.

The antenna measures about 80 inches in height from the

ground plate to the bottom of the parabolic dish. The satellite dish measures 60 inches in

radius and 20 inches in depth. LiNC estimates the

focal length of the dish to be 43.6 inches.

A 4 amp fuse box is located on the side of the motor casing. There is another fuse inside the antenna box

in the lower right hand corner of the wiring casing.

Wiring to the satellite dish restricts the rotation about

the azimuthal axis of the satellite dish. The motion is restricted to 360° by

an aluminum stop. Structural constraints restricted elevation to 0° - 90°. See

Figure 1 for locations of the pertinent antenna features.

The

total height of the satellite dish in the stowed position is 161 inches, or 13

feet and 7 inches. The stowed position has the bowl of the dish facing straight

up. The height from the ground plate to

the motor mount is 78 inches, or 6 feet and 6 inches. The radius of the

satellite dish is 60 inches. The depth of the satellite dish is 20 inches.

Upon the

inception of the Tracking Station, the US Air Force made a donation. Included in the donation were two high-gain Yagi antennae and one 3 meter parabolic satellite

dish. Each antenna would be used for

various missions of differing natures.

Also included were independent positioning units for the antennae. The

dish and the Yagis required assembly and installation on the roof of WRW. Graduate student Thomas Campbell headed the

installation process. The Yagi antennae

were mounted on the roof and integrated with computers and a radio in the

Satellite Design Lab by way of conduits leading from the roof to the Satellite

Design Lab (SDL). The Yagis are already capable of automated control and are

able to track satellites operating on VHF and UHF frequencies. Some of the satellites already tracked with

the Yagi antennae include amateur radio satellites.

Currently,

operation of the satellite dish motors is only possible through manual control,

which is accomplished with a switch designed and built by Mr. Campbell. The switch interfaces directly with the drive

motors by way of a nine-pin connector.

Unfortunately, this interface is on the roof of WRW and requires a

person to be stationed there for the duration of operation. Such a restriction makes it impossible for

one person to control both the radios and the satellite dish. Furthermore, for a satellite to be tracked

one would have to be constantly using the manual control. Such actions would required

the operator to have precise and detailed knowledge of the satellite

trajectory. Not one of these

requirements is practical and for all intents and purposes, impossible.

The

Satellite Tracking Station will not only be used by aerospace students, but

also by the aerospace department in projects such as Formation Autonomy

Spacecraft with Thrust, Relnav, Attitude, and Crosslink (FASTRAC) and Remote

Accessible Communications Environment (RACE).

FASTRAC is a departmental satellite design project in which

nanosatellites are designed and constructed as part of a nationwide collegiate

program sponsored by the Air Force. The

Air Force has given 12 colleges, including The University of Texas at

Austin, a

two-year grant to build two flight-ready satellites that will demonstrate

technologies to be applied in formation space maneuvers. Aerospace companies and the United

States government have been exploring

the potential of using numerous smaller satellites flying in formation in lieu

of larger, more costly satellites in future missions. The benefit of using smaller satellites

flying in formation is that the smaller satellites are expendable. That is, it is easier to replace a small

piece of a satellite array than it is to replace an entire system. The Tracking Station will be instrumental in

testing for FASTRAC and in communicating with the satellites after their

launch. RACE is a program in which the

UT aerospace department hopes to one day participate. This program will allow control via the

internet of the UT Tracking Station and stations at participating

colleges. In addition to these programs,

general use by aerospace students will make the Satellite Tracking Station an

invaluable educational tool.

LiNC is

a four-member team comprised of aerospace engineering undergraduate

students. Each member brings to the

group diverse experiences and talents.

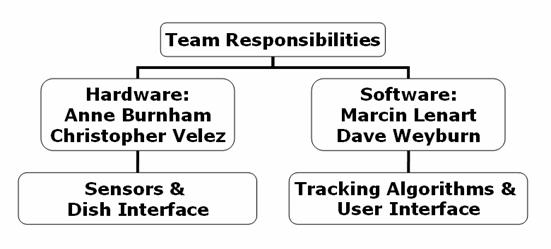

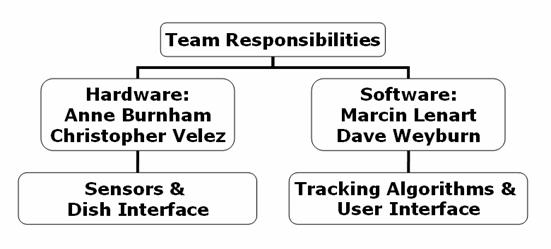

The team was split into two groups.

The first group worked primarily on the hardware for the project, while

the second group dealt primarily with the software development. While the members’ tasks were specific, they

are certainly not restrictive. The group

working on software was involved in the hardware development and vice

versa. Hardware development consisted of

researching, purchasing, fabricating, and installing any electronic or

mechanical parts. Team members working

on hardware were assigned acquire and install the sensor array and integrate

the sensors and satellite dish motor with the motion controller in the

SDL. Software development included

writing code to reposition the dish and evaluate algorithms for automated

satellite tracking. The members working

on hardware development were Anne Burnham and Christopher Velez. Marcin Lenart and Dave Weyburn worked on

software development. Figure 2 shows a

diagram of the team structure as it was defined at the beginning of the

semester.

Figure 2. Team Structure

Diagram

<previous Go

to Table of Contents next>

LiNC’s goal was to automate the motion of the UT

Aerospace Department’s satellite dish. An overview of the architecture of the satellite dish

motion-control system is shown in Figure 3.

The user inputs a set of commands, e.g., “move to a particular point” or

“track this satellite across the sky”, into the computer via the graphical user

interface. The motion-control

application sends these commands to the

motion

controllers. Current is applied to the

satellite dish motors by the motion controllers, and the dish moves according

to user specifications. The motors and

the sensors installed on the dish give feedback, by way of the motion

controllers, to the motion-control application.

After the application makes the necessary calculations with this

feedback, the user is shown graphical information about the satellite dish’s

current configuration. With this

information, the user can make decisions about what next should be done with

the dish.

To

better facilitate the completion of the motion-control system, LiNC decided to develop four smaller goals. The smaller goals were intended to focus the

LiNC team on the specific needs of the hardware and software. The goals of the LiNC team were: to design

and implement a satellite dish mounted sensor array, connect the dish and

sensor array to the motion controllers located in the Satellite Design Lab,

create a motion-control application and graphical user interface, and choose

and employ an appropriate method for generating satellite ephemerides for use

in the automated tracking of satellites.

The satellite dish is capable of more than 370o

of azimuthal movement. More than 370o of movement, however, will

cause damage to the dish wiring. To

prevent damage to the wires, the satellite dish must not over-rotate. Aluminum

stops on the dish currently serve this purpose. At the beginning of the

semester LiNC aimed to replace these stops with two arrays of magnetic sensors

that would monitor the motion of the satellite dish and prevent over-rotation.

The

plan defined by the LiNC team at the beginning of the semester called for

sensors to act as cutoff switches on the parabolic dish. These sensors were to be placed strategically

on the satellite dish. The positions of

two sensors would be determined by evaluating the total possible rotation of

the dish and the total required/desired rotation of the satellite dish. A third sensor would be placed at a home or

default position on the dish. Once the sensors

were installed on the dish, their circuitry would be connected to the motion

controllers in the Satellite Design Lab.

LiNC also planned to develop sensor housing. As the satellite dish is on the roof, the

circuitry will be susceptible to the elements.

Housing will protect the sensors without interfering with their magnetic

properties.

The remainder of the concerns determined by the hardware

team at the beginning of the semester had to do with the satellite dish motors

and their connection to the motion controller in the SDL. The motors are pulse-encoded, which means

that as the motors drive the dish, they send a signal in the form of a square

wave. LiNC decided that the pulse-to-degree ratio

would be used in the determination of satellite dish position. For this to occur, the drive motors would

have to be connected to the SDL lab in much the same manner the sensor array

would be connected. The difference

between the two connections would be that the connection from the drive motors

to the lab would go directly from a junction box, whereas the sensor array

would need to connect to a separate junction box before going through the first

junction box.

Once the team had the wiring from the sensors and the

drive motors connected to the SDL, it would have to be connected to the

National Instruments PXI-7344 motion controller by way of the nine-pin

connector in the SDL.

In order to control the satellite dish from a computer in

the Satellite Design Lab, a motion-control application needs to be

designed. This application will consist

of two parts: the front-end graphical user interface and the back-end program

that runs the show.

A graphical user interface (GUI) is a graphically

designed portal through which the user is able to interact with the larger

motion-control application. Other

user-end options do exist. DOS

interfaces and UNIX shells are two such options, but the CPU on which our

application will operate runs on Windows: as a result, we believe a GUI is the

easiest option to pursue and the most user-friendly.

The workings of the application already exist between the

user interface and the motion controllers.

Input from the user will be converted to commands that instruct motion

controllers to act on the motors.

Feedback from the motors and sensor arrays on the satellite dish via the

motion controllers will be interpreted for user readouts on the GUI

displays. This application will be able

to manually control the dish with on/off commands, tell it a specific point in

the sky on which to focus, and track a satellite across the sky.

The

objective of satellite tracking algorithms is to obtain azimuth and elevation

data from Satellite Toolkit (STK). STK is a sophisticated software package that

computes satellite ephemerides in a wide range of configurations. Figure 4

shows STK generated ground-tracks for a certain satellite. To obtain azimuth and elevation

data from

STK, it will be necessary to download online data for a satellite into the

toolkit. Once the azimuth and elevation

report has been created and saved for a given satellite and time period, it

will be imported into our software as a text file. LabVIEW-written code

will then interpret the data and use it to drive the antenna. The text file will contain enough information

for our software to create a sky-chart and ground-track plot. Before satellite

tracking can occur, however, motion sensors must be installed on the satellite

dish.

<previous Go

to Table of Contents next>

The hardware team designed two identical sensor arrays composed of three

Anisotropic Magneto-Resistor (AMR) sensors.

One array will monitor the horizontal motion of the satellite dish, and

one will monitor the vertical motion.

The array design is shown in Figure 5.

Figure 5. Sensor Array Design

The circle represents a top

view of the shaft of the dish. The Home

Sensor indicates when the satellite dish is in its default position. The two

Stop Sensors prevent the satellite dish from over-rotating and damaging wires.

The Team Advisors determined that the dish may rotate by 370° before damage

will occur. Therefore, the angle between the two stop sensors is equal to 10° to

allow for 370° of rotation.

The

team chose the AMR for several reasons. First, the high sensitivity of the AMR

provides immunity to the gap between the magnet and sensor. Second, the low

cost and high reliability are desirable. Third, the sensor is small in size and

has dimensions of only .244” x .196” x .068”. Finally, the AMR has no moving

parts that could wear out over time [Linear, 2000]. The team submitted a Sample

Request to Honeywell and obtained 6 free sensors. The specific Honeywell AMR

model we have requested is the HMC 1501, which is shown in Figure 6.

Figure

6. HMC 1501 Sensors [Honeywell]

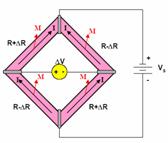

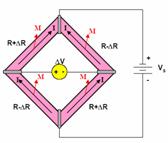

The AMR sensor is made by joining four Permalloy

resistors into a diamond shape to form a wheatstone

bridge configuration. The individual resistors are made by depositing a thin

film of Permalloy, a nickel-iron material, on a silicon wafer. The structure of

the AMR is shown in Figure 7.

Figure

7. AMR Sensor

[Applications, 2002]

The top and bottom of the

diamond are connected to a supply voltage, Vs, so that a current, I,

flows through the sensor. When a magnet passes the sensor, a second magnetic

field, M, is induced in the sensor, and ∆V is produced between the two

side contacts according to the following

(1)

(1)

where S = material

constant (12mV/V)

θ = angle between M and I

(degrees) [Applications, 2002]. By

placing an AMR sensor on the stationary base of the satellite dish and a magnet

on the rotating shaft, the direction of the magnetic field can be determined

from the output voltage. The HMC 1501 exhibits a 1.8

mV/° sensitivity [Linear, 2000].

The HMC

1501 contains one AMR bridge for a position sensing capability of θ equal

to ±45° [Applications, 2002]. The ∆V output versus θ is shown for a

Vs value of 5V in Figure 8.

Figure 8. ∆V Signal Output Versus θ

The graph shows that ∆V

is zero when the magnet is outside the ±45° range and θ is zero. When

θ is ±45°, the output voltage is at the maximum value of ±0.8 V.

There are three possible errors to consider when reading

the output signal. First, an offset error voltage may result from manufacturing

tolerances. The value of the offset will be determined through initial

experimentation. The motion-control application will compensate by adding an

error correction value to the output signal. Second, the material constant may

vary with temperature and affect the bridge sensitivity and offset error. The

coefficient of temperature for the bridge sensitivity is -.32%/°C, and of the

offset is -.01%/°C. The coefficient of temperature represents the percentage

error that will occur for each degree of variation from 25°C [Linear, 2000].

The method of compensation for this error is to be determined. Third, exposure

to a disturbing magnetic field could break down the magnetic alignment of the

Permalloy [Caruso, 1998]. The sensors will experience a disturbing field due to

the fact that the electromagnetic field of the dish motor and of the dish

controllers are completely contained within the housing.

The AMR

sensor operates in saturation mode, which provides two advantages: the sensor

is insensitive to the gap between the magnet and the sensor array and is

unaffected by the temperature coefficient of the magnet. The applied magnetic

field must saturate the Permalloy to make M align

with the external magnetic field and to produce reliable ∆V readings. A

minimum field of 80 Gauss is required for saturation [Applications, 2002].

To meet

this minimum magnetic field requirement, the hardware team chose .47” diameter,

.11” thick Neodynium magnets. The magnets provide

10,800 Gauss of residual magnetic induction and will be attached to the

satellite dish with epoxy. The team chose these magnets for their high strength

and small size.

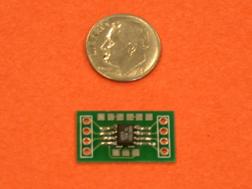

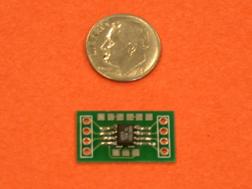

As seen in Figure 9, the pins of the sensor are flat and

must be surface-mounted. Figure 8 shows a sensor soldered to a surface-mount

board before testing. In the future, the surface-mount board must be mounted to

a PC Board before installing on the satellite dish.

Figure 9. Sensor Soldered to Surface-Mount Board

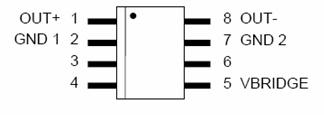

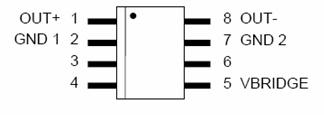

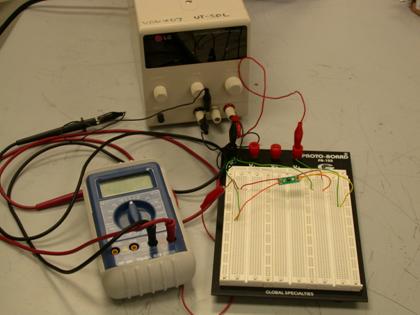

To test

the performance of the sensors, a surface-mounted HMC 1501 sensor was connected

to a voltage supply and to a multimeter. Pins 2 and 7 of the sensor were

grounded, and pin 1 was outputted to the multimeter. The voltage supply was

connected to pin 5 of the sensor. The pin-out drawing of the sensor is shown in

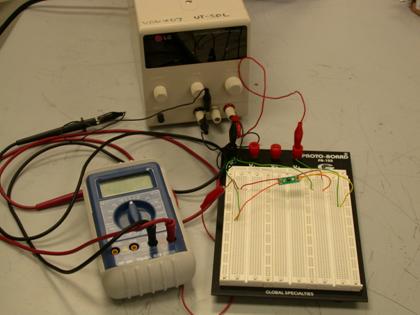

Figure 10, and the test setup is shown in Figure 11.

Figure

10. HMC 1501 Pin-Out Drawing

Figure

11. Sensor Circuit Test Setup

When the voltage supply was set to 5.0 Volts, the output

voltage of the sensor was 12.0 Volts. When the magnet was held an inch above

the surface of the sensor, a ∆V of ±0.4 Volts was produced. The ∆V

is too small for the motion controller to register so an amplifier circuit is

needed.

The sensors will be used outdoors and must be protected

from the environment. The design team has determined that the sensors should be

housed in 1” x 1” x 1” plastic

boxes. The sensor boxes should contain a water-tight seal and should have lids

with hinges in order to provide access for repairs. A ¼” diameter hole on the

side of the box will provide access for the voltage input/output wires to run

from the sensors to the antenna box. A rubber casing will protect the wires. In

the antenna box, the sensor input voltage wire is connected to the motor

voltage, and the sensor output voltage wire is relayed to the SDL.

The figure below depicts the future locations of the

sensor arrays on the satellite dish. The top circle and picture on the right

indicates the location of the vertical motion sensor array, and the bottom

circle and picture on the left indicates the location of the horizontal array.

The yellow arrows indicate the rotating surfaces on which the magnets will be

placed, and the purple arrows indicate the stationary surfaces on which the

sensor boxes will be located. The boxes will be affixed to the respective

surfaces with epoxy.

Figure 12. Sensor Array Locations

The satellite dish motors are pulse-encoded motors. The dish motors receive a 24 Volt input. The 24 Volt input powers the motors and

allows the satellite dish to move. Upon

receiving this input, the satellite dish then provides two outputs. The first output is movement. The second output is encoded pulses in the

form of square waves. These square waves

are created using rotary encoding.

Figure 13. Rotary Encoding

Figure 13 shows the process of

rotary encoding. A light source within

the drive motors sends light to a segmented disk. As the dish turns, the disk is turned

likewise. The segmented disk allows

light pulses through which are turned into an electrical signal and sent to a

squaring circuit. As the name would

suggest, this circuit produces the square wave pulses that are outputted by the

satellite dish as feedback. There are

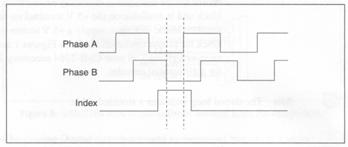

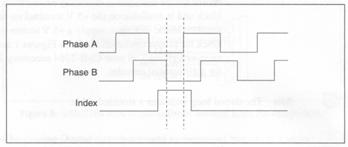

two types of rotary encoding: absolute and incremental. Incremental encoding motors send three pulses

as feedback: Phase A, Phase B, and Index (see Figure

14).

Figure 14. Incremental Encoding Pulses

The Index pulse acts as a

counter. Each pulse of the Index

corresponds to a rotation of the motor.

Phase A and Phase B are sent as feedback and are used to determine CW or

CCW motion. The second type of motor is

an Absolute Encoding motor. These motors

contain a segmented disk such as the one shown in Figure 15.

Figure 15. Absolute Encoding Disk

The Absolute Encoding disk

makes it possible to know to where the dish has been moved at all times. That is, each motor orientation has a unique

place identifier on the disk. A 5o

movement of the satellite dish has a unique place identifier as does the

movement of 6 o, 7 o, etc. This feature helps to avoid loss of

place. If there is loss of power, for

example, it is possible to determine exactly where the dish is based on the

position of the Absolute Encoding Disk.

This type of satellite dish motor would be ideal in that position

determination would be simplified.

The

satellite dish on the roof is an incremental encoding motor. There are two ways the incremental encoding

motor could send its signal. The first

method is called Single Ended TTL. This

method sends a single signal for each of the three feedback pulses (Phase A,

Phase B, Index). This manner of signal

feed is sufficient if the signal travels only small distances (less than 10

feet). The second method for signal feed

in an incremental encoding motor is the differential line driver method. This method sends two signals for each

pulse. For example, Pulse A would be

sent as well as Not Pulse A. This dual

signal system helps increase noise immunity over distances great than 10

feet. This method would be ideal for

sending feedback from the roof of the Aerospace building to the Satellite

Design Lab.

The

incremental motors on the satellite dish employ the Single Ended method. This could be a problem in that the distance from

the roof of the aerospace building to the SDL is much more than 10 feet. Also, the term “incremental encoding” motor

may be applied to the satellite dish motors erroneously (the term is referenced

in the literature supplied by the donator of the dish – the US Air Force). As described above, an incremental motor has

an index pulse. Based on tests performed

on the satellite dish motors it is the conclusion of LiNC that there is no

index pulse. Testing done on the

feedback system, however, has shown the existence of Phase A and Phase B. A nine-pin connector was made to take signals

from the pulse encoding lines and display them on an oscilloscope. The square waves outputted by the motors

during repositioning have been displayed on the oscilloscope numerous

times. These tests occurred on the

roof. Similar results have not been

duplicated in the SDL.

Research was also been done regarding integrated circuits

(ICs); specifically transistors and operational amplifiers. The team concluded that wear on the motors

can be reduced if voltage is applied gradually.

Currently, voltage is applied to the motors by way of relays. Relays are on/off mechanisms. When a relay receives 5 Volts, for example,

it then outputs 24 Volts. However, even

if a gradual voltage is applied to a relay the output is not sent until the

voltage reaches 5 Volts, and the output is instantaneous rather than

gradual. To overcome this obstacle, it

was initially thought that a transistor be used as a replacement. However, through discussions with Electrical

Engineering professors at UT, it was decided that operational amplifiers would

be a better choice.

At the time of the mid-term the plan was to use

transistors from Fairchild Semiconductors.

It has now been determined that operational amplifiers from National

Semiconductor will be the likely choice of IC.

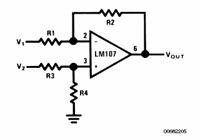

The component LM 741, an op amp made by National Semiconductor, has been

purchased. This component, along with

input from the technical support team at National Semiconductor, has made

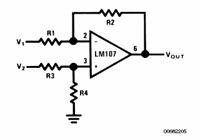

preliminary circuit designs of a differential amplifier possible. Figure 16 shows the basic circuit of a

differential amplifier.

Figure 16. General Differential Amp Circuit (courtesy

of National Semiconductor)

The differential amplifier

allows an output that is determined by a set of two input voltages. Because the inputs can be varied, the output

can be made more exact without having to determine the exact gain the op amp

needs to have. Figure 17 shows a chart

of varied inputs and the corresponding outputs for an op amp with a gain of 4

Volts. The chart demonstrates the

flexibility of the op amps.

Figure 17. Input/Output for an Op-Amp with 4 Volt

Gain

Power switches were installed on the roof to provide

access to the 120 Volts running to the Yagi and the

parabolic antennas, as well as a third, optional device. Since safely working on the electronics in

the antenna box requires power to be shut off, the addition of the switches has

been a big convenience. It is no longer necessary to contact University Power

Station to have the circuit breaker removed (a process that could take as many

as three days). The switches are

water-proof and mounted in an aluminum chassis that is

attached to the inside of an access box.

The chassis is easy to remove if further work or repair on the power

system becomes necessary. The figure

below shows a diagram of the wiring connections.

The power switch assembly was installed in the 120V power

box as indicated in Figure 18. Figure 19

shows the hardware in place. The left

switch activates the power running to the yagi

antennas; the center switch activates power to the parabolic antenna; while the

switch on the right activates power to an optional future device. Although 120 V runs through the power

switches, the highest-voltage electronics we actually worked on received 24

V.

The systems integration between the software and the

hardware groups involves an understanding of the parts and connections

involved. Commands from the software

travel to the PXI-7734 Motion Controller that is a circuit board inside the

National Instruments CPU. This device

sends and receives information, to and from the Lab View software and also

sends and receives signals from the UMI-7764 Breakout Box. The UMI-7764 Breakout Box is an interface

device that allows wiring to be attached to specific motor-control

inputs/outputs. Figure 20 shows the

breakout box as well as the connections used for the purpose of this project.

The wires connecting to the breakout box lead into the LED

adapter box. The team constructed this

device in order to provide the necessary outputs for the dish. As seen in Figure 20, there are two analog

outputs from the breakout box, one for each axis. These outputs vary in polarity, depending on

which direction command was selected by the user or software. The adapter box diverts the current into the

correct place on the nine-pin connector by using light emitting diodes. This

simple circuit is shown in Figure 21 with the nine-pin connector shown on the

left side of the schematic, and the corresponding breakout-box wires, on the

right.

In addition to converting the output, the adapter box

confirms sent signals via the light emitting diodes and provides a clean

connection to the breakout box as seen in Figure 22. The nine-pin cable from the adapter runs to

the juncture box (also called the j-box) where the signals are directed to and

from the roof. These commands consist of

a direct current signals that have 5 Volt amplitudes. Once on the roof, the signals reach the

antenna box where  they end up in the relay board. The relay board provides 24 Volts per signal,

which in turn travels to the motor housing and activates the motors. The relay board ramps up the voltage using

two sets of relays. A relay is a switch

that closes when a current is passed through its magnetic coil, activating a

circuit of higher voltage than that which activated the relay. Hence, the first set of relay switches are

activated by the 5 V signals from the controller. Once a 5 V relay is tripped, it allows a

higher voltage circuit to activate a 24 V relay, which in turn passes the

higher voltage signal to the motors. A

schematic of this relay circuit can be seen in Figure 23.

they end up in the relay board. The relay board provides 24 Volts per signal,

which in turn travels to the motor housing and activates the motors. The relay board ramps up the voltage using

two sets of relays. A relay is a switch

that closes when a current is passed through its magnetic coil, activating a

circuit of higher voltage than that which activated the relay. Hence, the first set of relay switches are

activated by the 5 V signals from the controller. Once a 5 V relay is tripped, it allows a

higher voltage circuit to activate a 24 V relay, which in turn passes the

higher voltage signal to the motors. A

schematic of this relay circuit can be seen in Figure 23.

The

outputs on the right of the diagram represent the four different motor commands

(elevation up, elevation down, azimuth right, azimuth left.) In order for the antenna control to function

properly, the closed loop system must be completed by sending pulse-encoded

information through a relay-board bypass inside the antenna box to a nine-pin

cable running down to the j-box in the lab.

From there, the signal travels down the original cable, through the

adapter box and into the Breakout Box.

Once the Motion Controller receives

the pulse-encoded information, national instruments software interprets it for

use in the antenna control program written by LiNC. This program includes a graphic user

interface shown below in Figure 24.

The

manual control functionality allows the user to directly send signals to the

motors. That means elevation and azimuth

changes can be made by commanding the antenna to move on that axis until the

button is no longer pressed. The GO TO functionality receives an azimuth and

elevation from the user and then positions the antenna accordingly. The tracking functionality would receive an

ephemeris data file location provided by the user, then

track the satellite while it passes over the station. This last functionality has not yet been

programmed.

Figure 25 reiterates the

abovementioned connection process. This

closed loop system receives commands from the user, sends them to the antenna

box via the controller, Breakout box, and adapter box. There, the relay board amplifies the signals

in a discrete way and sends them to the motors.

The motors position the dish, creating pulse-encoded information that

travels back down to the lab and into the controller. Finally, the antenna control software

interprets the pulse-encoded signals and converts them to antenna position data

that allows the program or the user to adjust the outputs.

<previous Go

to Table of Contents next>

The

team designed the software structure in a modular way such that each function

performs a major task of the satellite dish automation process. The software takes inputs from the user as

well as the dish motors and sensors.

Through a graphical user interface, the user may specify how to move the

dish or which satellite to track. Sensor

inputs let the software know if the satellite dish is getting too close to the

limits of its motion and when the dish is in its centered position. Placing sensors at the satellite dish’s

centered position (the home position) is important, because the function

keeping track of azimuth and elevation is reset when the dish is centered. Another reason why home sensors are important

is that the satellite dish is stowed in the centered position. The centered position is at an azimuth of

180º and an elevation of 90º or when the dish is pointing straight up. Outputs are sent to the user to inform of the

azimuth and elevation angle at which the satellite dish is currently set. The software also allows the user to know

when and to which position the antenna is moving. Since the computer sends commands to the

antenna motors while receiving information from both the motors and sensors and

uses that received information to evaluate further commands, the system is

considered to be a closed-loop system.

The structure of the software reflects this fact. Three main antenna control

modules - the user interface and the optimization and angle counting functions

- work together to send and receive information to and from the user as well as

to and from the dish. Figure 26

illustrates the interconnectivity of these software components.

The

MOTOR CONTROL function is the lowest level of antenna-motor control available

in the software. In addition to

receiving commands from the user interface this is the only module that sends

commands directly to the motors (via the controller hardware interface). The MOTOR CONTROL module sends commands to

the motors to move them, specifying which direction each motor should move

(clockwise/counterclockwise) and at what velocity. This part of the code also

Figure 26. Software Architecture Flow Diagram of

Function Interconnectivity

ramps the

input voltage up and down to prevent unnecessary wear-and-tear on the motors

and their surrounding hardware.

The

GO-TO module serves a slightly more sophisticated purpose. Given azimuth-elevation input from the user

interface, this function activates the motor control module in such a way that

the motors are spun in the necessary direction and stopped when the desired

azimuth and elevation are reached.

Top-level

satellite dish automation takes place in the FOLLOW module. This module receives data from a text file

consisting of azimuth-elevation positions with their corresponding times. The data expresses the path of a satellite as

it moves across the sky over the tracking station. These position pairs are sent periodically to

the GO-TO function at the correct times, making the satellite dish follow a

satellite overhead.

Information

is received from the motors in the pulse-encoded feedback that was previously

mentioned in the Automated Motor Tutorial.

The COUNTER function receives these pulses and keeps track of them. Encoded pulses allow the COUNTER function to

determine which way each motor is spinning and how far it has gone. Based on the motor and satellite dish servo

properties, the ANGLE function converts this information into the dish’s

current azimuth and elevation. The ANGLE

function recalibrates the azimuth and elevation based on sensor inputs.

The

Motion Optimization Joint Operation module (MOJO) receives data from both the

ANGLE module and the sensor array as seen in Figure 25. MOJO tracks the satellite dish position and

movement in relation to the physical limits of dish operation. This function will deactivate any of the

satellite dish-control functions (MOTOR CONTROL, GO TO, and FOLLOW) if it knows

the dish is moving too close to the edge of its prescribed region of

operation. This module also makes sure

that the path taken by either the GO-TO or FOLLOW functions does not move the

satellite dish past its stops. Keeping

track of current dish position in relation to dish motion limits and

calculating shortest distance to a given azimuth and elevation optimizes the

motion of the antenna so that it never needs to approach a desired position

from one direction only to have to stop and reverse course because a motion

limit has been reached.

In

conjunction with the design of the software architecture, we developed a

preliminary graphical user interface (GUI).

A representation of this plan can be seen in Figure 27. We decided that the program should consist of

a single user panel that would contain all the information required for all

three types of motion-control.

Figure 27.

Preliminary Graphical User Interface

In the

upper, left-hand corner is located the Manual

Control option. This option is a

computerized version of the previous method of controlling the satellite dish

(up-down/left-right paddle from the roof).

The user has the option to toggle on and off switches that correspond to

clockwise or counter-clockwise motion in the horizontal plane (azimuth) and up

and down motion in the vertical plane (elevation). Motion will be able to take place in two

planes at once, but only one button will be operable at a time in any given

plane.

Directly below the Manual

Control section is the second motion-control option. In the Go

To window the user can specify a particular azimuth and elevation at which

the satellite should point. The Cancel button allows the user to abort a

move. If at any point in time during a

go-to motion the user decides to change the go-to location without previously

selecting the cancel button, the satellite dish will simply transition to the

newly entered location. Azimuth

indicates the horizontal plane location, and elevation indicates the vertical

plane location.

The third motion-control option is Tracking, and it is located

across the bottom of the window. A user

selects a text file that contains a prescribed set of azimuth and elevation

locations for given times that can be followed to track a satellite across the

sky. Once the Track button is toggled, the motion-control program will begin to

evaluate the selected file and maneuver autonomously. The In

View LED will indicate whether the tracking station is currently tracking

an in-view satellite (a satellite that is above the local horizon). Range

displays the straight-line distance between the satellite dish and the

satellite it is tracking. In Transit specifies the time left until

the satellite comes into view. On the

right-hand side of the Tracking

window the user will be able to evaluate a ground plot of the entire path of

the satellite currently being tracked.

This display may also show a handful of the ground tracks of the

station’s previously tracked satellites.

The Tracking option also has a

Cancel button, which, by toggling,

will abort a tracking exercise.

All three motion-control options contain an Activate button. The activate button brings focus to one

particular mode of motion and removes focus from the others. This feature serves two purposes. First, the motion-control application will

never need to be concerned with conflicting requests from multiple motion

functions. Reduced complexity reduces

the ways in which the program can fail.

Secondly, user error is removed from the equation on at least one

front. A user will need to actively

disengage the Activate button (thereby

bringing all satellite dish motion to a stop) before selecting a new mode of

operation. In the deactivated state,

only the Activate buttons for the

three motion options will have focus.

The user will have the option of bringing into focus any of the three

types of motion by selecting one of the three corresponding Activate buttons. This three-motion option deactivated state is

also the view with which the user will be presented upon first launching the

application.

Finally, we have the Sky

Chart in the upper-right quadrant of the screen. The sky chart will indicate the current focus

of the satellite dish with red crosshairs on a polar chart. The scope of this chart is the range of the

satellite dish. Current azimuth and

elevation are indicated in displays at the bottom of the Sky Chart. When the

satellite dish is in motion, the Antenna

Moving LED will light up. If the

motion-control program is tracking a satellite, the ground track for that

satellite inside the dish’s range will be shown on the current position chart.

Having settled on a software design, we needed to select

a software platform with which to program.

Developing the motion-control application with LabVIEW

quickly became the obvious choice. LabVIEW is a National Instruments development package that

uses pictures to program. Arranged in a

flow-diagram manner, LabVIEW code removes the need

for standard written code, though such code can still be interfaced with the LabVIEW pictures. Originally,

coding with a standard programming language such as C, C++, Java, or Visual

Basic had been considered, but when it became evident that the motion

controllers, also provided by National Instruments, were pre-packaged with LabVIEW functions, choosing the LabVIEW

environment was the easy decision to make.

The prepackaged LabVIEW functions are called

NI-Motion, and they are the functions that, when called on, actually generate

motion. An added bonus to LabVIEW is that the creation of a GUI goes hand-in-hand

with the drawing of the application code.

Boxes and buttons referred to in the code are automatically included in

the GUI. In fact, the act of designing

the user-interface is what generates corresponding item pictures for use in the

program’s flow diagram. [Bishop, 2004].

The current GUI for the motion-control application can be

seen in Figure 24. Manual Control, Go To,

and the Sky Chart have been fully

developed. The Follow function has yet

to be written, but a few of the items that will be a part of the completed

routine have been placed in the application GUI to give a good idea of how the

whole program will look in the end.

Those functions that have been completed have stayed true to the

original concept for the most part. As

the full application is developed further,

more

functionality will be added to the GUI so that it more perfectly mirrors the

concept drawing.

The GUI is driven by a LabVIEW

event structure that sits and waits for user input. All of the GUI buttons have entries in the

event structure so that if the button is pushed, some bit of code is

triggered. For instance, if Button A is pushed, release Button B. Figure 28 is the block diagram of the GUI

event structure. With one exception, all

code executed inside of the GUI event structure pertains entirely to the GUI

display. This exception happens to be

displayed in Figure 28. The GO HOME

event directly calls an NI Motion function that takes the dish to its home

position. All other calls to NI-Motion

Figure 28. GUI

Event Structure

position. All other calls to NI-Motion functions are

done outside of the event structure, even though they may be triggered by a GUI

event.

The software team decided that the first programming task

to complete would be to replicate the manual motion-control box previously used

to control the satellite dish from the rooftop of the Aerospace Department’s

building. Manual motion-control is the

most primitive control option for the satellite dish, and successfully creating

this functionality is a significant step in fully automating the dish.

Figure

29 is a screen shot of the basic Manual

Control GUI. Manual Control is the GUI side of the MOTOR CONTROL function. After the GUI event structure processes a

button click, the code behind the display runs through a series of

Figure 29.

Manual Control Graphical User Interface

nested if-than statements that pinpoint the

necessary action required of the satellite dish. This section of the code can be seen in

Figure 30.

Figure 30.

MOTOR CONTROL Block Diagram

The

toggle switch directly under the Manual

Control label is the Activate

button described in the Preliminary GUI

Design section of this report. The

green LED next to the toggle switch indicates when Manual Control has been selected.

Toggling the Activate switch

to the left turns off the LED and resets and removes focus from the four

directional buttons (they are deselected and fade into the background). When Activate

is toggled on, only one button of a pair (up-down, left-right) can be selected

at a time.

After

the MOTOR CONTROL function was written, the software team decided to work on

the GO TO function. Figure 31 is a

screen shot of the Go To GUI. The Go

To

Figure 31. Go

To Graphical User Interface.

GUI interfaces with the GO TO

function. Code for the GO TO function is

rather straightforward. Figure 32 is the

block diagram for the GO TO function. If

the Go button is clicked, only one if-then statement is executed. Elevation

and Azimuth are run

Figure 32. GO

TO Block Diagram

through sub-VIs that convert the angle input to counter output for use

by the motion controller (recall that the motion controller works with motor

pulses or counts, not angles). The Go Home button executes directly from

the GUI event structure as was previously mentioned. Clicking on Go Home returns the satellite dish to its home position (El =

90˚, Az =

0˚). Currently, the Reset button sets the values in Elevation and Azimuth to zero, but this button will soon be changed to a one with

ABORT functionality. An Abort button will stop the dish from

moving towards whatever the previously selected azimuth and elevation position

was. Finally, the Activate toggle switch at the top part of the GUI gives and takes

away focus to the Go To

interface. If this switch is toggled off

while satellite dish motion is taking place, the dish will stop. The LED next to the Activate switch indicates whether the Go To interface is active.

The Sky Chart can be seen in Figure

33. The sub-VI that drives the polar

graph in this display is a modified version of a prepackaged LabVIEW polar graphing VI.

A

Figure

33. Sky

Chart GUI

few

simple changes to the code allows for the display of the cardinal directions

(N, S, E, W) and removes all numbering from the graph. Figure 34 is a picture of the block diagram

that continuously updates the Sky Chart. The UPDATE CHART function polls the

motion-control software for the dish’s current position. Counter responses from the motion controller

for the azimuth and elevation locations are fed through sub-VIs

Figure

34.

UPDATE CHART Block Diagram.

elevation locations are fed through sub-VIs that convert counter input to angle output. Those angles are then converted to 2D polar

coordinates and displayed on the graph as a red line whose terminus is the

location of the dish’s focal point.

Graph divisions are in 15˚ increments on both axes. The azimuth and elevation for the dish’s

focal point location are also displayed in the Azimuth and Elevation

boxes below the graph.

The FOLLOW function is not yet

written. The GUI components seen in

Figure 28 are for show only at this point.

In addition to the fact that time ran out this semester, a number of

other obstacles remain in the way before FOLLOW can be finished properly. Some of these complications are discussed in

sections 6.0 and 8.0 of this report.

The only change to the

overall architecture that the software team has made is that the MOTOR CONTROL

function will be interfacing with the motor separately from the way in which

the GO TO and FOLLOW functions do. Previously,

FOLLOW was to call GO TO and GO TO would call MOTOR CONTROL to move the

satellite dish. Sticking with this

original plan would have provided greater complexity than having GO TO access

the motor in a different manner than the way MOTOR CONTROL accesses the motor. Our initial concern was to avoid repeated

functionality, but having learned more about the NI-Motion software that comes

with the motion controllers, the fact has become clear that most of the

functionality we thought we would need to create is already provided by the

NI-Motion software. Changing this aspect

of our software architecture greatly reduces the amount of code we need to

write; therefore, having two different functions operate the motors differently

is not a serious deviation from our original goal.

Over

the course of the semester various test apparatus were evaluated for their

ability to work out any problems with the software. All hardware testing was done on the MOTOR

CONTROL function only. Before any of the

other software functions can be tested, the simplest function needs to work.

At

first, a simple electronic circuit was created to test the MOTOR CONTROL

function. The test circuit represented

the two satellite dish motors as light emitting diodes (LED). For each motor two diodes were used. One diode represented forward motion and the

other represented reverse motion (one light per direction). The setup of this test apparatus can be seen

in Figure 35. This test was MOTOR CONTROL’s first successful operation of virtual

motors. The success was limited,

however, because the motion controller was not receiving the necessary motor

pulses (see Section 4.7) needed to sustain motion. After about five seconds, the controller

would time out and the LEDs would shut off.

Figure 35. National Instruments

Controller-LED Software-Test Circuit.

Having completed our first test, we began searching for

encoded feedback motors that could truly simulate the dish motors. We were not able at this time to begin testing

on the satellite dish, because the dish-controller interface was still not

functioning properly. Small motors that

we were able to acquire, such as the one in Figure 36, did not work with our

software. Regardless of whether the

motors had pulse-encoding, the software

was

incapable of performing as it was intended to.

With NI’s Measurement

& Automation Explorer (MAX), which can be seen in Figure 37, the motors

could be tested without the software.

This alternative source of command provided proof that the

Figure 37. NI Measurement & Automation Explorer

software was

not at fault for failing to drive the motors.

The motors did not respond to MAX driven input either, and as a result,

our team discovered that the voltage supplied by the controller was a limiting

factor in how we could control external hardware. Learning about the characteristics of the

motion controller through trial and error helped to develop a plan of action

for finally testing the software on the satellite dish.

The motion-control literature indicates that the PXI-7734

controller operates at +/- 10V. This

voltage drops when the motion controller is placed in series with a significant

external resistance. When the motion controller

was tested on the diodes, no significant voltage drop occurred across the

diodes, because diodes do not have a large resistance. Motors, however, do have a significant

resistance. While testing the motion

controller on the small motors, we observed that the voltage across the motors

would drop to about 4V, which was not sufficient enough to drive these

motors. Because we knew that the

satellite dish’s amplifying relay board requires 5V to operate, we decided to

check to see if the motion controller’s 4V was adequate enough to trigger the

relays on the board. Two of the four

relays worked, which meant we could now partially operate the satellite

dish. After the circuit was modified so

that all four relays worked, we decided it was time to test the software on the

satellite dish.

The dish moved on the very first attempt at

software-controlled motion, only to time out five seconds later. We were not surprised, though, because no

pulse-encoded feedback was connected to the controller from the satellite

dish. Motion was, and still is, possible

on both axes, though only for five-second intervals. The intervals do not have to be spread out;

they can be rapidly executed back to back.

Later in the report, we talk a bit about what we are trying to do to

perpetuate future satellite dish motion.

<previous Go

to Table of Contents next>

Although an open loop system between the computer

and the antenna has been set up and tested successfully, motor feedback has not

yet been achieved. Several problems

regarding the pulse encoding method restrict the current system

functionality. To begin, the National

Instruments software expects an index pulse as one of the motor responses and

as of yet, LiNC has not been able to identify an

index pulse coming out of the motor connection cable. The wiring connections in question are shown

in Figure 38.

The

connections make no accommodations for an index pulse. Although it might be possible to double one

of the existing pulses as the index, current attempts at signal return have

been unsuccessful.

Another dilemma arose due to the

inconsistency of the pulses. The team

tried several times to analyze the pulse output on the roof using an

oscilloscope. The pulses could be observed

during only half of the attempts. This

in consistency could be attributed to our testing method or the oscilloscope

settings. However, there exists a

distinct possibility that the motor-encoding apparatus or connections are

faulty. This would present a much bigger task for future development. Furthermore, the pulse-encoded signal could

never be obtained in the lab. This could be associated with the previous

problem. However, signal degradation could occur aver the cable lengths

involved in the system. This possible

signal loss can be prevented by winding the pulse cables around each other, by

using shielded cable in the lab, and by keeping the control CPU within 10 feet

of the juncture box.

There is also a mechanical problem

with the elevation mechanism. Mechanical pins control the range of elevation

motion. These pins are positioned with solenoid servos, one of which is not

functioning, as shown in Figure 39. This means that the satellite dish cannot

execute a full 0 - 180° elevation turn. However, 0 - 90° motion is attainable and

sufficient for most antenna applications.

In addition, the satellite dish was exposed to extreme gusts

from the storms moving through the Austin area during the weekend of the 24th of

April. The resulting vibrations caused

the pin connecting the elevation servo arm to the elevation joint mount to come

loose and fall out. The pin acts as a

structural member and without it the dish looses support in the elevation axis. The loss of structural support caused the

dish to come to rest on the support ring around the motor housing.

The pin was replaced and Loctite

applied to the ends of the pin. Loctite is a liquid

sealant that hardens to form a waxy stopper in junctures such as the elevation

connection.

Damage was caused to the transmitter support beams causing

the transmitter/receiver dome to come out of focus. Refocusing the satellite

dish will be a key step after remote automation is achieved.

<previous Go

to Table of Contents next>

Future

design teams may use this report to fabricate the sensor boxes and circuit

boards, and to install the sensor arrays and magnets on the dish. Because the

∆V outputted by the sensor is only 0.4 Volts, future teams will also need

to design and install an amplifier circuit to amplify the output voltage of the

sensors before relaying it to the SDL.

Integration

of the sensor array and drive motor feedback system to the SDL must be

completed. Integration includes

replacing the relay board, and determining the exact pulse/degree ratio. In order to replace the board we must

determine exactly how power is delivered and any additional functions the board

performs must be determined. These

details are crucial in the development of an op-amp based board. The op-amps, as well as any other

miscellaneous parts (PC board, resistors, etc.), that will be used in the

fabrication of the replacement board must be chosen and purchased. National Semiconductor op-amps have been used

in the preliminary design phase and will likely be used in the fabrication

phase as well. The replacement board

must then be fabricated and installed in the motor control box on the roof.

The pulse/degree ratio must also be determined. Signals sent by the motor have been displayed

on an oscilloscope. The pulse-encoded

feedback will likely be used as the index required by the software. In order for these pulses to be used as the

index the exact pulse/degree ratio must be determined. The pulse-encoded feedback has been

inconsistent and the cause of this inconsistency must also be determined.

Once the satellite dish motor has the correct circuitry

and the sensors have been installed they must each be integrated with the

motion controller in the SDL. Wiring

already in place will be used to connect the sensors and the motor to the

lab. The adapter box will have to be

modified to fit the additional wiring from the roof and to provide appropriate

connections between the hardware and software.

<previous Go

to Table of Contents next>

The next step in software

development is trouble shooting the MANUAL CONTROL and GO TO functions. Although we have managed to move the

satellite dish with our current software configuration, there may be sneak

circuits in the code that up to this point have gone unnoticed. Because the NI-Motion software continues to

time out before any major kinks can be evaluated, we are left without the

ability to successfully fix any bugs in the code. NI-Motion software is counterintuitive in

many cases and the reference manuals provided by National Instruments are far

from helpful. In fact, the only source

of information that provides any kind of support is the Help file (NI-Motion

Help can be accessed through the LabVIEW

interface). The Help file is just barely

useful, and so misuse of the NI-Motion functions is almost guaranteed. Regardless, further progress with the

software will most likely have to be put to the side while the

hardware-software interface is the main focus of work on the satellite

dish. Debugging cannot take place until

sustained dish motion has been achieved, and currently the bottle neck in the

design process is the problematic hardware-software interface.

The function that drives the Sky Chart GUI is going to take some time to fully complete. At the time this report was written, the display

only indicated the position in the sky at which the satellite points. The user readout will need to include the

information for whatever satellite the dish is currently tracking. This satellite tracking information is

detailed in the following section. The Sky Chart GUI functionality, previously

referred to as UPDATE CHART in the earlier Software section, cannot be

completed until the FOLLOW function can import external satellite ephemerides. In

addition, the Sky Chart cannot be tested until the satellite dish is capable of

sustained motion. Until that time, the Sky Chart will only be a static display

of a polar graph.

The ultimate goal for tracking is to give the user load-and-track

capabilities. This means that the user

will be able to select a satellite after loading its information into the

program, and track it by simply clicking the appropriate button. STK creates a file of azimuth, elevation, and

range data with respect to time. The

part of the LabVIEW software that will handle the

loading and interpretation of the data file is still to be written. Although Satellite Toolkit can generate such

a file, the automatic generation or downloading of satellite ephemerides would greatly simplify program operation. Writing the algorithm that will actually

interact with the GO-TO function to track the satellite across the sky is also

an important next step.

The

tracking software will also need graphic screen outputs. Our group will write

code to display the ground track of the satellite based on its two line

elements, indicate when the satellite is in range for the ground station (that

is, when the satellite rises in the local horizon), output the sky-chart for

the satellite, and show its range from the station. The information to create these charts will

be obtained from the same text file as the azimuth and elevation data. Graphical output will require some

calculations to be performed inside our program. The code to handle this will be written with LabVIEW’s Virtual Language (VL). VL is different than the normal graphical LabVIEW code and requires some extra work to use properly.

<previous Go

to Table of Contents next>

Although LiNC established the

foundation for satellite dish automation, there remains much work for closed-loop

tracking capability to be realized.

Currently, signal degradation and the lack of an index pulse pose the

biggest obstacles. LiNC

suggests pulse wire twisting, shielded cables, and maximum CPU proximity to the

Juncture Box to combat any possible signal loss problems. Furthermore, all twelve of the pins from the

motor (as shown in Figure 35) should be examined during motor operation to

ascertain whether or not an index pulse lurks in one of the signals. In the case that no index pulse exists as predicted,

the following options should be evaluated.

1.

Double one of the

existing A or B pulses as the index.

Plug either the A or B cable into the INDEX plug inside the Breakout

box.

2.

Create an artificial

index using a function generator. Create

a square wave with an amplitude of 1 V and a period of

1 millisecond. Adjust the period until

the correct response results.

3.

Operate without the

index. The antenna open-loop control

system currently operates by moving the antenna at 5-second intervals before

signal cut-off resulting from lack of feedback.

This may be sufficient to sustain tracking capability. If the GO-TO and TRACKING functions call the

MOTOR CONTROL function for intervals of less than 5 seconds, tracking and go-to

capability could be achieved through the use of discrete antenna

movements. The existing pulses would

then serve to determine the antenna position through either existing LabVIEW functions, or if necessary, programmer adapted

algorithms.

4.

Abandon the Motion

Control Software and Controller board.

An Input-Output port on the CPU (I/O port) could receive the signals and

signal analysis functions could be written in C++, C, FORTRAN,

Java or another language. This would

avoid the incompatibility between available signals and existing LabVIEW prewritten analysis functions.

LiNC recommends trying each

of these plans in the order they are listed.

If successful feedback or feedback

emulation is achieved, the following software needs to be completed:

- A LabView TRACKING function that reads a text file and

loads azimuth and elevation data with a time index into arrays. The arrays

can then be sent to the GO-TO function at the appropriate time.

- The source of the

tracking file can be a user written program that creates sky-chart data

based on 2-line elements downloaded from the web. Satellite Toolkit software can also be

employed to create a sky-chart file.

- Motion Optimization

Joint Operation (MOJO) must be written in order to assure correct azimuth

and elevation synchronization. This

code will determine if TRACKING or GO-TO inputs cause the satellite dish

to reach the limits of motion and if so, find the best alternate path.

LiNC

advises that while experimenting with new software-system integration, a person

remains on the roof to observe the antenna location and deactivate the power

switch located in the power box (see Figure 17) if remote deactivation fails

and/or the antenna runs up against its stops. LiNC

recommends that a camera be installed on the roof to improve the user interface

with the motion control system.

<previous Go

to Table of Contents next>

The

Design of Everyday Things is a book that deals with the psychology of how

people interface with machines, the design principles that make that interface

natural and straight-forward, and the design mistakes that make some designs

fatally flawed for use by real human beings [Norman,

2002].

The

Graphic User Interface is our systems control mechanism for the user. The

design of this interface was discussed previously in Section 5.4. Let us explore some of the reasons for this

design. Note that the manual control, go-to, and tracking sections are

accessible in their own sections of the GUI. This sectioning provides a

physical map that tells the user that only one level of control can be accessed

at a time. Physical maps appear in well designed controls that provide visual

clues as to the effects of their operation [Norman,

2002]. It is insufficient to provide good physical mapping: the user must also

be reminded of the operation of the interface [Norman,

2002]. A reminder is that the virtual push-buttons on the screen that activate

each level of satellite dish control pop out on all windows except the one that

the user is currently accessing. In other words, activating a level of control

by pushing the activate button on any one level, causes all other levels to

deactivate and their activate buttons to pop up. Other examples of physical

maps that appear in our interface are the manual motor control buttons. The

buttons are oriented in a cross where up, down, left, and right buttons move

the satellite dish in the corresponding directions. These buttons also have

mutually exclusive pop-up properties. This means that it is impossible for the

user to attempt to drive a motor in two directions simultaneously. Such

features are also examples of designing against failure. It is infinitely

better to make it impossible for the user to make a mistake, rather than

designing the system to handle certain errors [Norman,

2002]. Installing sensors on the dish that let the software know when the

antenna is about to reach the limit of its motion so that the program can kill

the engines is just another example of this design philosophy. The operator

does not have to worry about damaging the satellite dish, because the

automation-system was designed to make user-inflicted damage impossible.

Allowing

the user feedback about his or her actions is an important feature of good

design [Norman,

2002]. Without system feedback, the user can never be certain that the controls

are performing the desired tasks. This can lead to frustration and incorrect

use of the interface. Our user interface is armed with several displays that

show the user when buttons have been pressed. Lights on the buttons light up

and the buttons themselves appear to be depressed when activated. Numerical

output is dynamically updated as the satellite dish is moving to allow the user

to know when and how the motors are in operation. In addition to this, a

crosshair on the sky-chart provides a back-up visual cue as to the position

azimuth and elevation position of the antenna. Finally, a tertiary signal in

the form of a display light indicates when the system is in motion. All this is done to ensure that the user

knows of the effect of his actions.

In

spite of the designer’s best attempts, sometimes the user makes error. This is

not the fault of the user for to err is human [Norman,

2002]. Dealing with user mistakes is one of the engineer’s most important

goals. This is also evident in our system. Each one of the control-level access

windows features a cancel button in order to stop all antenna motion when the

user realizes that an undesired input has been entered. Since user errors are

inevitable, being able to reverse ones mistake is utterly necessary.

User-centered

design is designing for a specific group of people and optimizing the design

around that group [Norman,

2002]. The group of users for our system will be aerospace engineers with

elementary knowledge of orbital mechanics.

This means that the operators, will have a general knowledge of how the

satellite dish should work including what azimuth and elevation mean, what

range is, what a sky-chart and ground track look like, and when a satellite

will be in view. If some of this knowledge is not present, a help file will

dispense any and all myths about satellite tracking terminology as well as the

various function available to the user via the GUI. Such users will most likely

be interested in accessing the satellite-tracking window at the bottom of the

GUI. Accordingly this window was made the largest and easy to identify. Since

people obtain much of the information from the world around them [Norman,

2002], we made sure to include a plethora of visual cues in the design by

methodically labeling all windows, buttons, display lights, and charts.

<previous Go

to Table of Contents next>

Most of

the hardware and equipment necessary for the successful completion of the

project has been donated. The U.S. Air

Force donated the satellite dish, and National Instruments donated the

controllers, the CPU, and the breakout box.

The Sample Request for the HMC 1501 sensors was successful, and LiNC received 6 free sensors. The cost for the project was

negligible.

<previous Go

to Table of Contents next>

Figure 40 shows the timeline for the entire semester. The dates listed across the top row of the

table indicate the week that the activity occurred. The team did preliminary

research during the last week of January and throughout February. The bulk of

the work in designing the motion-control application occurred throughout the

months of February and March. Testing and troubleshooting of the sensors and

motion-control application occurred throughout April, and the final results and

conclusions were made during the first week of May.

|

|

Task Name

|

Start

|

Finish

|

1/26

|

2/2

|

2/9

|

2/16

|

2/23

|

3/1

|

3/8

|

3/15

|

3/22

|

3/29

|

4/5

|

4/12

|

4/19

|

4/26

|

5/3

|

|

1

|

Define Project Goals

|

1/28

|

1/30

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2

|

Read Instruction Manuals

|

2/2

|

2/13

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3

|

Prelim. Presentation

|

2/4

|

2/4

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4

|

Troubleshoot N-Motion Control

|

2/6

|

2/13

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5

|

Research Sensors

|

2/9

|

2/24

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6

|

Begin LabVIEW work

|

2/13

|

2/17

|

|

|

|